As semiconductor components continue to shrink, the need for precise atomic-scale measurements has never been more critical. Modern chip designs push the limits of miniaturization, demanding extreme precision in layer thickness, doping concentration and defect detection. Traditional metrology techniques struggle to provide the resolution needed for structures measured in angstroms rather than nanometers. Erik Hosler, a leader in advanced metrology and semiconductor process control, mentions that atomic-scale metrology is essential for ensuring reliability, efficiency and performance in next-generation semiconductors.

Table of Contents

The Limits of Traditional Metrology

The transition from 7nm and 5nm nodes to even smaller architectures presents unprecedented challenges for metrology. Conventional optical and X-ray techniques, while effective for larger structures, often lack the necessary precision to inspect atomic-scale features accurately. As feature sizes approach physical limits, quantum effects, material inconsistencies and surface variations become more pronounced, requiring new metrology solutions that can measure at the atomic level.

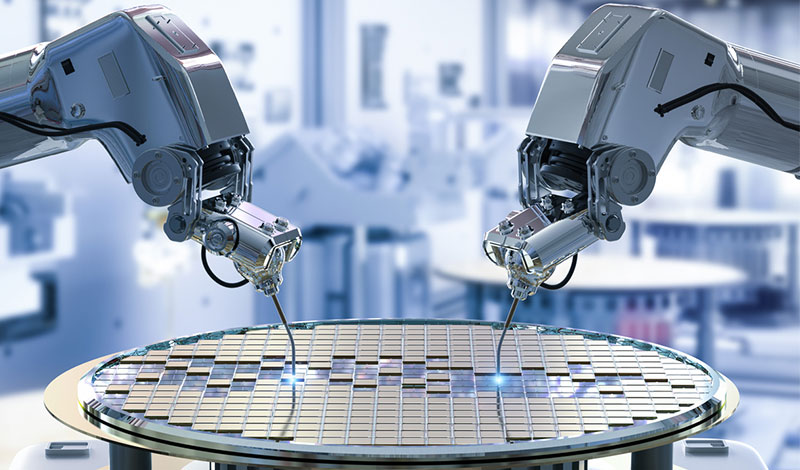

Another challenge is the increasing complexity of 3D-stacked transistors, Gate-All-Around FETs (GAA FETs), and high-density interconnects. These structures demand metrology tools that can inspect buried layers and detect atomic-scale defects without physically altering the sample. Non-destructive, ultra-high-resolution techniques are now essential for maintaining yield and reliability.

Breakthroughs in Atomic-Scale Metrology

To address these challenges, the semiconductor industry is adopting advanced metrology techniques capable of atomic-scale precision. One of the most promising developments is scanning probe microscopy (SPM), which allows direct atomic-level measurements of surface structures. By leveraging atomic force interactions, SPM provides high-resolution imaging without the limitations of traditional optical techniques.

Additionally, high-resolution transmission electron microscopy (HR-TEM) is enabling researchers to visualize individual atoms within semiconductor materials, providing unparalleled insights into defect formation, material interfaces, and crystal structures. This technique is crucial for optimizing material deposition and identifying defects at an atomic scale.

AI-Driven Precision in Atomic Metrology

Artificial intelligence is playing a key role in optimizing atomic-scale metrology. Machine learning algorithms analyze massive datasets from metrology tools, identifying patterns and anomalies faster than conventional methods. AI-driven defect classification improves process efficiency and helps fabs make real-time adjustments, reducing waste and improving yield.

“Leveraging artificial intelligence in both transistor design, device layout, and the overall manufacturing and process control technology will reshape semiconductor manufacturing,” says Erik Hosler. By integrating AI into metrology processes, fabs can achieve higher accuracy, faster inspections, and improved decision-making at the atomic scale.

The Future of Atomic-Scale Metrology

As semiconductor technology moves toward angstrom-level precision, metrology must evolve to keep pace with increasing miniaturization. Future developments will likely involve quantum-based measurement techniques, ultra-sensitive electron microscopy, and AI-enhanced process control. These innovations will be essential for ensuring the success of next-generation chips, quantum computing devices, and advanced AI processors.

Atomic-scale metrology is no longer a luxury—it is a necessity for driving semiconductor innovation forward. As new materials and architectures emerge, these measurement techniques will play a vital role in pushing the boundaries of Moore’s Law while maintaining the precision and reliability that modern electronics demand.